Bottle the value of plastic waste

How does it work?

Our technology unlocks the value in mixed plastic’s hydrocarbon chains, converting waste into a range of value-added materials:

1. Waste plastic to virgin-plastic remanufacturing additives: propylene, ethylene, styrene, polymeric waxes. All supporting waste transformation into a reusable circular economy.

2. Waste plastic to fuel: diesel, kerosene, Sustainable Air Fuel (SAF), gasoline, renewable fuels used as energy, transport and electrification

3. Waste plastic to Hydrogen and to Syngas.

4. Waste plastics as additives for biogenic renewable fuels and recoverable chemical for household products.

Our process is thermal catalytic, a low energy, low temperature high yield process. The waste is processed in 4 phase changes. Solid sized reduced heterogenous waste plastic is turned into a liquid, then a long chain hydrocarbon gas. The process of gasification reacts with our catalysts and transforms it into short-chain liquids and gases. The advanced process engineering achieves outstanding conversion rates and low energy ratio efficiencies.

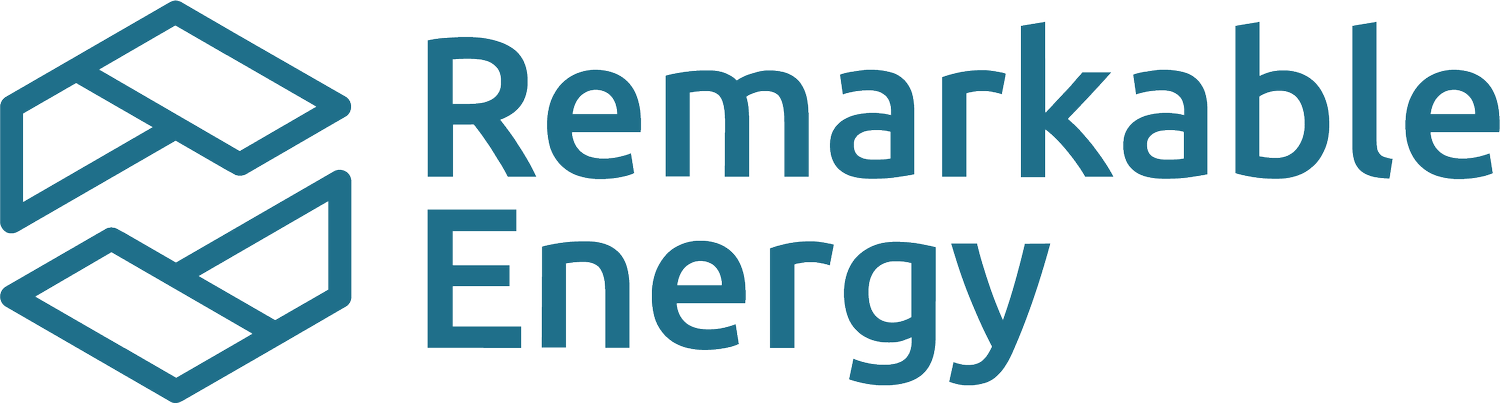

Plastic to fuels and electricity

Waste Plastics previously had little or no value, Plastics are made from oil, a solidified battery of energy. The Remarkable Energy technology reverse engineers the process and constructs a range of fuels, primarily Gasoline, Kerosene and Diesel.

All of the fuels have value, in marine, transport, SAF - to off grid power generation for electric vehicles

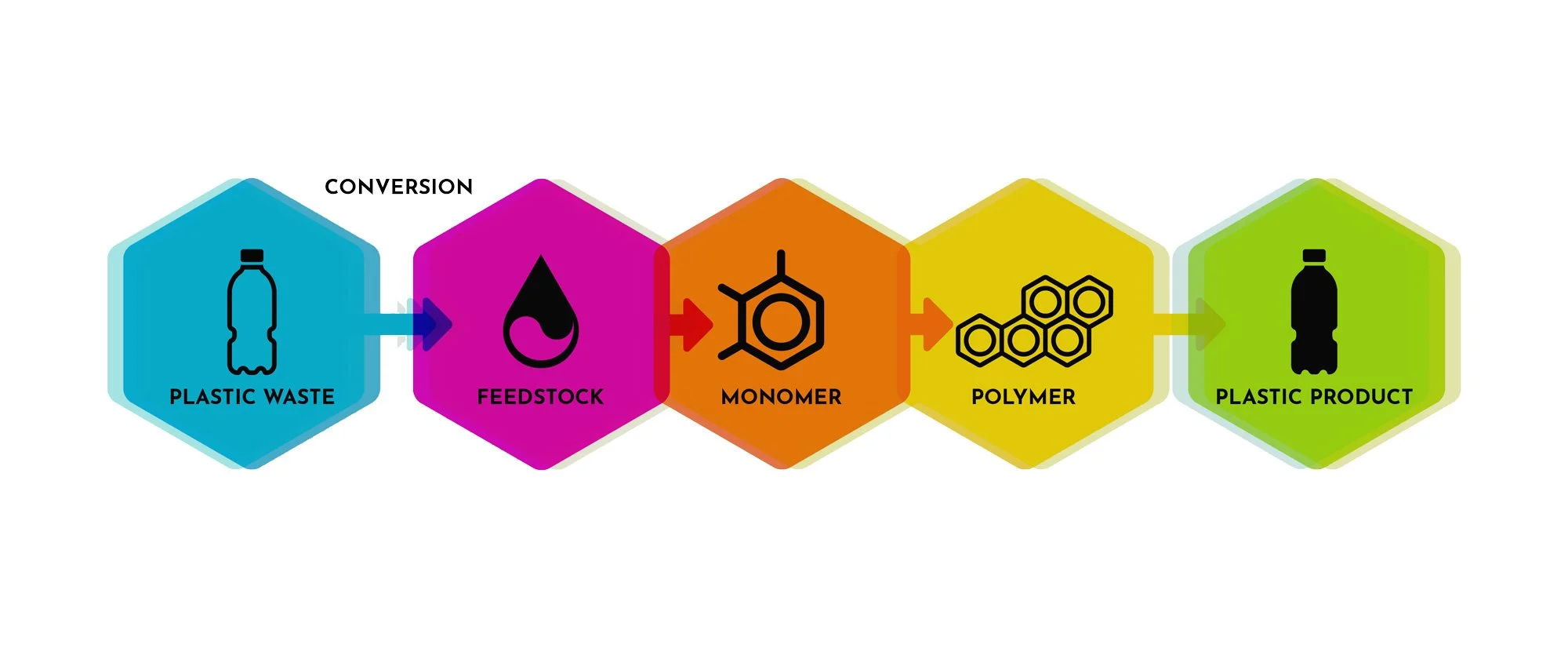

Plastic to Virgin plastic

Our process converts the Waste plastic into a virgin feedstock which then is reused in plastic remanufacturing. A circular solution to reusing multi-layered and technically impossible, by convectional mechanical methods, to recycle waste plastics. The mixed waste plastic is reversed back to the monomer building blocks Propylene, Ethylene, Styrene and bitumen waxes. Theses monomers are then rebuilt into polymers. This is a step forward in supporting waste transformation into a reusable circular economy.

With the first option to export waste to developing countries, waste management systems are failing, based on searching for more sites to dump recoverable waste. With incineration and Energy from Waste (EfW) flawed due to energy inputs, waste plastics are set to become an increasing problem. We are a UK business, bridging the gap between future-proofing waste management and viable refinery of recoverable waste.